Application scenarios

Treatment of Beneficiation Process Drainage

Tailings Pond Overflow Management

Mine and Plant Drainage Clarification

Closed-Loop Water Recycling Systems

The main sources of mineral processing wastewater include process drainage from beneficiation operations, overflow from tailings ponds, and plant/mine drainage. To alleviate water scarcity in mining operations and reduce wastewater discharge, it is common practice to purify and recycle this wastewater.

Solution

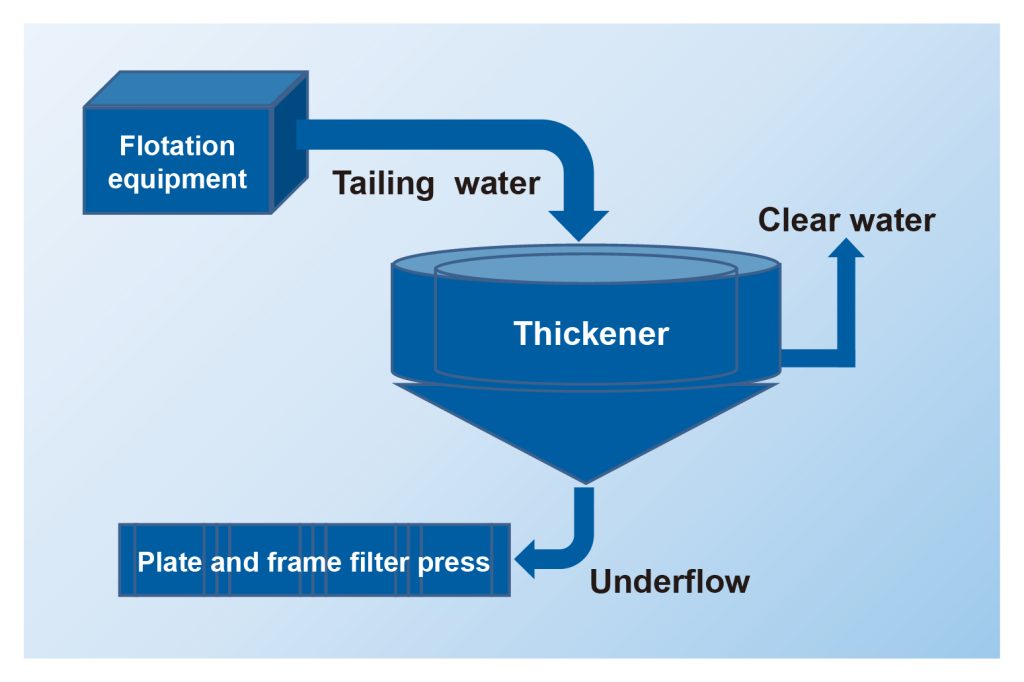

The purification processes for mineral processing wastewater mainly include: (1) a closed-circuit system combining hydrocyclones and thickeners in series; (2) dehydration using gravity sedimentation equipment; and (3) tailings pressure filtration.

Both Process (1) and Process (2) require the assistance of polyacrylamide (flocculant) to enhance dehydration. It accelerates the flocculation and sedimentation of suspended solids, reduces the solid content in the supernatant, and increases the concentration of the underflow.

| Product Name | Performance Features | Applicable Range |

|---|---|---|

| Anionic Polyacrylamide (APAM) | Wide molecular weight range: 6–20 million | Suitable for wastewater containing inorganic suspended solids |

| Cationic Polyacrylamide (CPAM) | Molecular weight: 10–13 million; Ion degree: 5%–80% | Used for wastewater systems with organic suspended solids |