Application scenarios

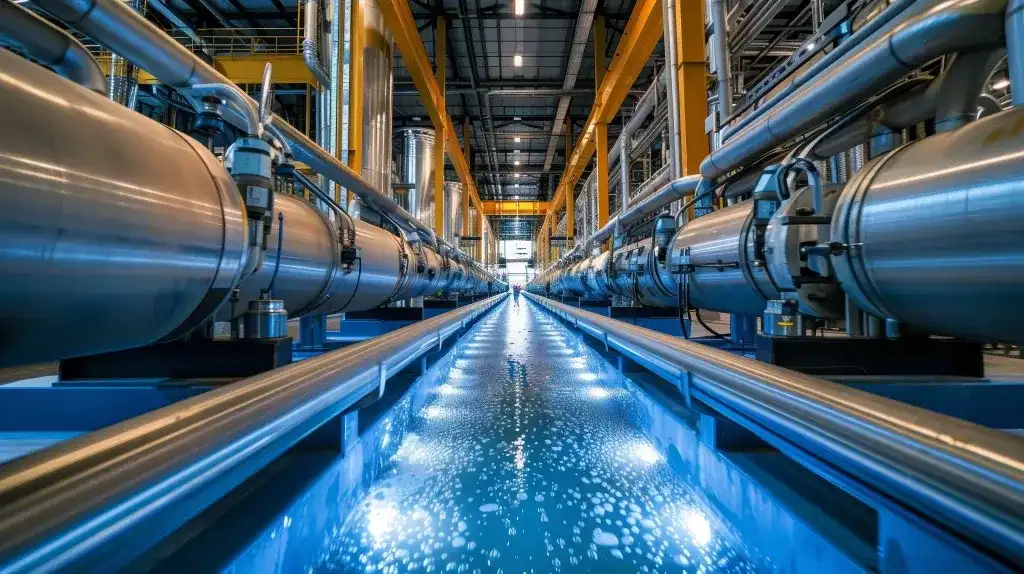

Oily Wastewater Separation

Papermaking, Dyeing, and Food-Industry Wastewater Treatment

Light Suspended Solids Removal

Enhanced Efficiency in Pretreatment and Tertiary Treatment

Industrial wastewater (e.g., from papermaking, dyeing, food processing): Enhances the removal of COD, color, and other pollutants by improving the flotation efficiency of fine, light particles or colloids that are difficult to settle.

Wastewater pretreatment or advanced treatment: Used to remove lightweight suspended solids that are hard to eliminate through conventional sedimentation, thereby improving the efficiency of subsequent treatment processes.

Solution

Polyacrylamide (PAM) serves as a highly effective flocculant in the air flotation process. Through mechanisms such as charge neutralization and adsorption bridging, it optimizes floc structure and bubble adhesion efficiency. This significantly enhances solid-liquid separation efficiency, improves effluent quality, and reduces the load on the flotation unit. PAM is generally used in combination with inorganic flocculants. Initially, inorganic flocculants destabilize and coagulate sludge particles to form preliminary aggregates. Subsequently, PAM strengthens the flocculation process, enabling micro-particles enriched by bubbles to rapidly aggregate into larger flocs. This results in clear effluent with reduced turbidity.