Acrylic Acid

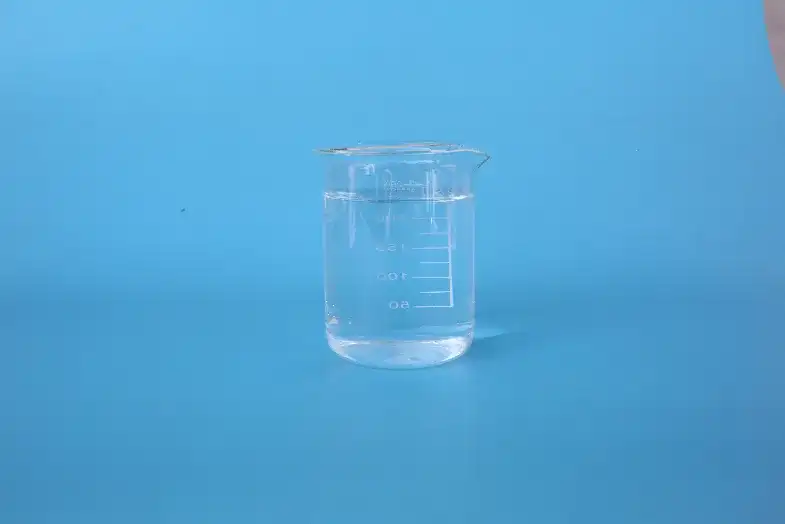

Acrylic acid is the simplest α,β-unsaturated carboxylic acid. It is a colorless, transparent liquid at room temperature and atmospheric pressure, with a pungent acidic odor and highly corrosive nature. Acrylic acid is a key petrochemical raw material and an important intermediate in organic synthesis.

Our Advantages

- Strong hydrophilic properties.

- Excellent polymerization and copolymerization capabilities.

- Flexible molecular design. By chemically modifying carboxyl or double bonds, a series of derivatives are generated.

Scope Of Application

Acrylic acid is primarily used as a raw material for:

Acrylate esters

Superabsorbent resins (largest downstream application)

Other applications include:

Water treatment chemicals

Detergent builders

Coatings and paints

Adhesives and sealants

Textile and leather processing

Oil recovery

Plastic modification

Papermaking chemicals

Technical Indicators

| Item | Unit | Specification |

|---|---|---|

| Appearance | – | Colorless, transparent liquid |

| Acrylic Acid Content | % (wt) | ≥99.5 |

| Moisture | % (wt) | ≤0.3 |

| Color (Pt-Co) | Hazen | ≤15 |

| Inhibitor (MEHQ) | ppm (wt) | 200 ± 20 |

| Aldehydes (as Furfural) | % (wt) | ≤0.002 |

| Dimer | % (wt) | ≤0.3 |

Usage Method

Acrylic acid is mainly used as a reactive feedstock in closed production units at chemical plants and is transported through pipelines. Its use involves specialized chemical processes, including continuous polymerization, esterification, and distillation.

Certifications & Trust Endorsements

Our company has obtained multiple internationally recognized management system and compliance certifications, including:

- ISO 9001 Quality Management System Certification

- ISO 14001 Environmental Management System Certification

- ISO 50001 Energy Management System Certification

- ISO 45001 Occupational Health and Safety Management System Certification

Our acrylic acid products meet stringent international quality standards and comply with relevant chemical regulations, including:

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals)

- GMP / Chemical Industry Standards for purity and safety

These certifications and regulatory compliances demonstrate our company’s comprehensive capabilities in quality management, workplace safety, environmental responsibility, and international compliance, providing customers with safe, reliable, and high-quality chemical products.

Call to Action

For sample testing, technical support, or quotations, please contact our sales team.

FAQ

Q1: How should acrylic acid be stored?

A: Acrylic acid should be stored in a cool, well-ventilated area, away from heat, sparks, open flames, and incompatible materials. Containers must be tightly closed and protected from moisture.

Q2: What is the shelf life of acrylic acid?

A: The product is stable for 12 months when stored under recommended conditions.

Q3: Is acrylic acid safe to handle?

A: Acrylic acid is highly corrosive and requires proper personal protective equipment (PPE), including gloves, goggles, and protective clothing, when handling.

Q4: Can acrylic acid be used for superabsorbent polymer production?

A: Yes, acrylic acid is a primary monomer in the production of superabsorbent polymers (SAP).

Q5: What precautions are necessary during transportation?

A: Acrylic acid should be transported in approved containers, protected from sunlight and moisture, and in accordance with local hazardous materials regulations.