Remote sites present significant challenges for effective water treatment, demanding robust and adaptable chemical solutions. We understand that logistical complexities, environmental sensitivities, and operational constraints necessitate specialized approaches. Our focus is on how emulsion polyacrylamide can provide superior performance in these demanding environments, ensuring efficient water management and sustainable operations.

Remote Site Water Treatment Unique Challenges

Remote water management operations face distinct hurdles not encountered in conventional settings. Logistical constraints chemical supply are paramount; transporting and storing bulk chemicals to off-grid water purification sites is often difficult and costly. Environmental conditions can be extreme, ranging from arid deserts to frozen tundras, impacting chemical stability and equipment performance. Furthermore, limited infrastructure at these locations restricts access to specialized personnel and reliable power sources. These factors collectively complicate effective water treatment, requiring solutions that minimize footprint and maximize operational resilience. We recognize that traditional powder flocculants often exacerbate these issues due to their handling requirements and dissolution times.

Emulsion Polyacrylamide Superiority for Isolated Operations

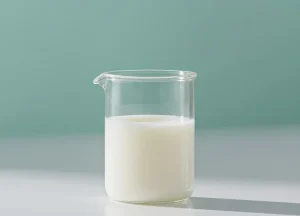

Emulsion-type polyacrylamide offers distinct advantages over powder forms, particularly for remote oilfield water treatment and other isolated applications. Our emulsion polymers, produced using advanced water-in-oil (W/O) emulsion technology, feature rapid dissolution rates, typically ready within 5–15 minutes. This significantly reduces preparation time and equipment needs compared to powder polyacrylamide, which requires extensive mixing for proper dissolution. The liquid flocculant benefits include easier handling, precise dosage accuracy, and reduced dust hazards, enhancing safety in challenging environments. Polyacrylamide storage challenges are also mitigated; emulsions are more stable and less prone to caking or degradation in varying temperatures. Shandong Nuoer’s high molecular weight emulsion-type polyacrylamides ensure high flocculation efficiency and long-term stability, critical for consistent performance in remote settings.

| Feature | Emulsion Polyacrylamide | Powder Polyacrylamide |

|---|---|---|

| Form | Liquid (water-in-oil emulsion) | Solid (granules) |

| Dissolution Rate | Fast (5-15 minutes) | Slow (30-60 minutes, requires agitation) |

| Handling | Easy, pumpable, precise dosing | Dust hazards, requires careful handling |

| Storage | Stable, less prone to caking | Susceptible to moisture, caking, degradation |

| Equipment Needs | Simpler dosing systems | More complex dissolution tanks and mixers |

| Safety | Reduced dust inhalation risk | Potential dust explosion and inhalation risk |

Critical Selection Criteria for Remote Emulsion Polymers

Selecting the optimal emulsion polymer for remote wastewater treatment remote locations requires careful consideration. Key factors include the polymer type (anionic, cationic, non-ionic, or amphoteric), charge density, and molecular weight. For instance, Cationic Polyacrylamide Flocculant is effective for positively charged suspended solids, while anionic types suit negatively charged particles. We customize production to meet specific customer requirements, ensuring the polymer’s properties align with the water matrix. Environmental compatibility is crucial; low residual monomer content in our products ensures environmentally friendly application. Proper polymer selection guidelines and flocculant dosage optimization are critical for maximizing treatment efficiency and minimizing chemical consumption, especially where resupply is difficult.

Article Recommendation: If you are interested in our commitment to sustainable practices and community development, we invite you to read about our recent initiatives in “《Nuoer Group Donates 300000 RMB to Rongzhuang Village》.”

Deployment and Performance Optimization in Remote Settings

Effective deployment and performance monitoring flocculants are vital for remote site chemical dosing. Proper dosing techniques involve continuous monitoring of influent water quality and treated effluent to adjust polymer feed rates. We recommend using automated dosing systems where feasible, minimizing manual intervention and ensuring consistent polyacrylamide application techniques. Adequate mixing is essential for optimal floc formation; insufficient mixing can lead to poor performance, while over-mixing can shear flocs. Regular performance assessments, including turbidity measurements and sludge volume index (SVI), help maintain peak efficiency. Our emulsion polymers are designed for ease of use, contributing to reliable performance even in challenging conditions.

Environmental Compliance and Sustainability in Remote Use

Operating in remote, often pristine environments, necessitates strict environmental compliance flocculants and sustainable water treatment remote practices. We ensure our polyacrylamide products have low residual monomer content, minimizing potential environmental impact polyacrylamide. Adherence to local and international regulatory frameworks is paramount. We advocate for responsible chemical management, including proper storage, handling, and disposal protocols, to safeguard sensitive ecosystems. Our commitment extends to developing products that contribute to a smaller environmental footprint, aligning with global sustainability goals.

Article Recommendation: Discover how our advanced technologies and commitment to innovation are showcased at major industry events by reading “《Nuoer at 25th China International Petroleum & Petrochemical Technology Exhibition》.”

Future Trends in Remote Site Polymer Technology

The future of remote site polymer technology focuses on advanced flocculant technology and smart water treatment solutions. Innovations include developing more concentrated and stable emulsion formulations, further reducing transport volumes and improving shelf life. Remote chemical delivery systems, such as drone-based or autonomous vehicle delivery, are being explored to overcome logistical challenges. Integrating smart sensors and IoT platforms will enable real-time performance monitoring and predictive maintenance, optimizing dosing and minimizing downtime. These advancements will enhance the efficiency and sustainability of water treatment in increasingly isolated operations.

Partner with Shandong Nuoer for Advanced Water Solutions

Shandong Nuoer Biological Technology Co., Ltd. stands as a global leader in Polyacrylamide Supplier OEM innovation, offering a comprehensive range of emulsion polymers engineered for the most demanding remote site applications. Our expertise, backed by an annual production capacity of 200,000 tons of Polyacrylamide Emulsion and a robust global sales and service network, ensures reliable, high-performance solutions wherever your operations may be. Partner with us to achieve unparalleled water treatment efficiency and sustainability in your remote projects. Contact our specialists today to discuss your specific needs and discover how our advanced polyacrylamide solutions can optimize your operations. Phone: +86-532-66712876 | Email: enquiry@nuoer.com

What are the specific challenges of using polyacrylamide in remote environments?

Using polyacrylamide in remote environments presents unique challenges including logistical difficulties for transport and storage, the need for robust and reliable dosing equipment, varying water quality and environmental conditions, and ensuring minimal environmental impact. Emulsion polyacrylamide, due to its liquid form, often mitigates many of these issues compared to powder alternatives.

How does emulsion polyacrylamide compare to powder forms for remote applications?

Emulsion polyacrylamide offers significant advantages over powder forms for remote applications. Its liquid state allows for easier handling, more precise dosing, and reduced dust hazards. It also typically requires less dissolution time and equipment, making it more efficient and safer to deploy in isolated locations with limited infrastructure. Shandong Nuoer’s high-quality emulsion polymers are designed for superior performance in such conditions.

What factors influence the cost-effectiveness of emulsion polyacrylamide on remote sites?

The cost-effectiveness of emulsion polyacrylamide on remote sites is influenced by several factors: transport costs (often lower for concentrated emulsions), reduced labor for preparation and dosing, minimized chemical waste due to precise application, and improved treatment efficiency leading to lower overall operational costs. The long-term performance and reduced maintenance of equipment also contribute to its economic viability.